Positive pressure Leak Tester commercial|multi pressure leak tester : manufacturing ASTM F2096 – Bubble Leak Tank to test the integrity of sealed packs using a positive pressure via a needle/tube inserted in a pack. Includes water tank and bench . VIERNES 23 DE FEBRERO DE 2024 3.22 (2:22) MULLINGAR (A7) 480m Flat CAJON ULTIMAS CARRERAS GALGO MEJOR TIEMPO 33242 Phoenix Pearl 29.82 23251 .

{plog:ftitle_list}

WEBQuando tenho direito à indenização por greve na Westjet? Você tem direito a uma indenização por greve se: Você teve um voo que sofreu transtorno devido a uma greve de funcionários da Westjet. Seu voo sofreu atraso igual ou superior a 3 horas ou foi .

ASTM F2096 – Bubble Leak Tank to test the integrity of sealed packs using a positive pressure via a needle/tube inserted in a pack. Includes water tank and bench .Find your pressure leak tester easily amongst the 158 products from the leading brands (JW FROEHLICH, CETA, ATEQ, .) on DirectIndustry, the industry specialist for your professional .

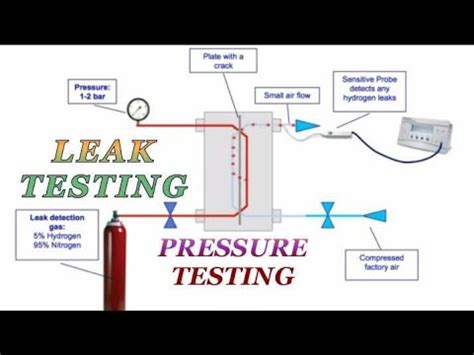

Step 4a — Typical Positive Pressure Testing: Connect one end of the orifice tube to the duct system using a short piece of single-wall flexible duct. The arrow on the calibration sticker .the system cannot pull a vacuum at any step and returns to atmospheric pressure, which is an indication of a leak, test for and repair the leak using the previously described procedure with tracergas. • If the 1000-micronvacuum holds for 30 minutes, break the vacuum with dry nitrogen to a pressure of 2 psig.Guide to good leak testing Commercial and industrial refrigeration and air conditioning systems leak too much refrigerant – leaks of up to 30% of the charge during a year are not uncommon. Leak rates do not have to be this high. Adherence to best practice in service, maintenance leak testing and repair can significantly reduce refrigerant losses.Air leak testing is a common method used for leak testing. It is a flexible test method that can be used to leak test a wide variety of parts and applications. Under the umbrella of air leak testing are several specific methods. In this ebook, we’ll cover the following types of air leak testing: > Pressure Change Method A

Per ANSI/ASHRAE Standard 90.1-2010, “positive pressure leakage testing is acceptable for negative pressure ductwork”. Even so, you will see specifications that may require return air or exhaust systems to be leak tested under a vacuum (negative pressure). To perform a proper duct leakage test under negative pressure using an ORIFLOW duct leakage tester, perform .

Step 5 — For positive pressure tests (5a), the fan discharge should be con-nected to the orifice tube. For negative pressure testing (5b), the fan intake will be connected. With McGill AirFlow’s 4-inch Leak Detective test components, the fan comes equipped with a tapered nozzle, which can connect to either

The cuff leak test is used to predict risk of post-extubation stridor in intubated patients. Use and interpretation of the test needs to take into account the overall context of the patient's condition and the management implications . Positive End Expiratory Pressure (PEEP), Pulmonary Mechanics, Pressure Vs Time Graph, Pressure vs Volume . Leak testing is a broad term that includes a multitude of technologies. For the purposes of this article, different leak test methods will be referenced but not described in full detail. This article defines the broad term leak test and takes a closer look at the pressure decay leak test method. Furthermore, this article will describe how a pressure decay test works, .• Insert positive pressure source with monitor into test sample • Submerge test sample in water; apply air to target pressure; hold for pre-determined time • Observe for continuous stream of bubbles. Test (External Vacuum): ASTM D3078 • Submerge test sample in water or other suitable fluid in vacuum chamber

Find your pressure leak tester easily amongst the 158 products from the leading brands (JW FROEHLICH, CETA, ATEQ, .) on DirectIndustry, the industry specialist for your professional purchases. . Kanomax is introducing a new Duct Air Leakage Tester (DALT) for commercial duct systems. The instrument provides step-by-step test conguration and . Rob Siegel. In my book Just Needs a Recharge: The Hack Mechanic™ Guide to Vintage Air Conditioning, I make the case that those “A/C recharge .95” signs you see at service stations are perilously close to fraud. If a system needs to be recharged, it’s because the refrigerant has leaked out, so the leak first needs to be found, then needs to be fixed.

Model: Internal Chamber. Dimensions (mm) Specification: BLT-P400: 420(L) x 320(W) x 300(H) ASTM F2096 – Bubble Leak Tank to test the integrity of sealed packs using a positive pressure via a needle/tube inserted in a pack.

InterTech’s family of M1075, MED75, M1045, and ECO Leak Detection instrumentation offer leading edge, proprietary technology for the optimum leak testing solution.. Leak testing measurement capability from 0.005 sccm to 200 sccm and flow measurement capability from 200 sccm to 100 slpm with ISO 17025 traceable calibration and, less than 5% Gauge R&R. .Guide to good leak testing Commercial and industrial refrigeration and air conditioning systems leak too much refrigerant – leaks of up to 30% of the charge during a year are not uncommon. Leak rates do not have to be this high. Adherence to best practice in service, maintenance leak testing and repair can significantly reduce refrigerant losses.

HVAC duct leakage testing is a critical maintenance task that ensures system efficiency, reduces energy costs, and prolongs the lifespan of your HVAC unit. This post outlines the importance of duct leakage testing and describes the tools, such as duct blasters, manometers, and smoke machines, needed to detect and locate leaks. It provides a step-by . Leak testing is a Non-destructive Testing method or process where inspectors apply pressure to an object to locate defects that are causing leaks. . or other type of flaw, the liquid or gas it is holding can leak out. This .

One leak test method may be better than another depending on the physical characteristics of the device, the materials of which . An excellent example of temperature and pressure changes is a commercial car wash and its impact on externally mounted sensors for driver assist and autonomous vehicle systems. Performing a Positive Pressure Test to Search for Leaks Last updated Dec 22, 2020

vacuum leak tester

The instrument’s vacuum pump evacuates the test chamber or fixture, drawing any leaking tracer gas through the analyzer (USP <1207.2>). The absolute leak rate of the test sample may be calculated by normalizing the test results by the partial pressure of the tracer gas within the test sample at the time of test (USP <1207.2>).the test pressure. The photo shows a suitable pressure testing gauge / regulator assembly. If you are using a manifold ensure it is suitable for the pressure and does not have a sight glass. You should use the gauge on the manifold to monitor the test pressure (the gauge on the regulator has a very small scale).Another option is to use the positive-pressure leak test. A test gas is used to fill the apparatus being inspected and to build up a slight positive pressure; the test . Positive pressure testing is, on the other hand, a technique commonly employed in tank engineering. When dealing with large containers and the long test periods they require . NiGen walks through nitrogen leak testing and nitrogen pressure testing methods & covers why nitrogen is used. Contact us for expert help! CALL US: 713.956.8022. Menu. 713.956.8022. Home; . nitrogen is used within commercial and residential buildings to protect their fire suppression lines and sprinkler heads from the damage that can be .

leak test instrument for industrial quality controlafter 46 years, and 250,000 testers installed in more than 5,000 customers worldwide, ateq presents its revolutionnary leak tester range : the f6 series including a compact leak tester f620, a weatherproof leak tester f610 and the f670 in its 19″3u industrial format. It is a simple test that is easy to automate and ideal for isolating even the smallest leaks. You can conduct pressure decay testing using either air pressure or a vacuum. Applications for Pressure Decay Leak Testing. As the name suggests, pressure decay leak testing detects leaks by measuring changes in pressure either inside or outside of a part. This video is a demonstration of the falling drop positive pressure liquid leakage test of ISO 80369-20:2015, Annex C using the Enersol – S16B – Falling drop.DEZEGA recommends using the UPG leak tester to test regularly for leak tightness on waist-worn self-contained self-rescuers. . The user manual describes the construction and requirements for everyday use of the positive pressure leak testing device UPG for self-contained self-rescuers. Languages: EN, RU, TR, UK, ES. as-upg-124 .

In the event of a leak in the test item, positive pressure inside the test item causes airflow into the isolator system. Sterile system leak test (aseptic applications) . Manufacturer’s catalog cuts and instruction sheets for all commercial components. Electrical, mechanical, P&ID’s and assembly drawings; Photo Gallery. Related Products. 1.1 This practice describes a method for determining the leakage rate of a vessel subject to a positive pressure difference. The technique is based upon evaluation of the change of mass within the test object based on a pressure decay measurement. The pressure decay measurement uses the ideal gas equation of state and the measured pressures, temperatures, .

lego star wars at te drop test

lego star wars clone turbo tank drop test

03/09/2023. IMAGENS FORTES! Ladrão passa mal e morre .

Positive pressure Leak Tester commercial|multi pressure leak tester